Well, turned real warm on Saturday and sunday, so it would seem that the initial set was good (it did form up to almost thumbnail hard in 6 hours), was hard on Saturday, and rock hard sunday).

So I learned of the incompatibility between polyester resin gelcoat and epoxy AFTER i used the epoxy, so now have a dilemma and a problem.

Dilemma- Do i drill out epoxy and refill with something that gel Coat will adhere to?

Do i spend the money on a small amount of paint like interlux, that is compatable?

Long term I want to do whatever is the proper fix.

Short term-Heres the problem. I am literally out of money for this project. As is always the case I am finding, these projects tend to expand quickly and mine is almost double what I budgeted.

My tank replacement turned into a tank replacement, new vent fitting, new fuel fitting, repair and replace a thru hull, bilge pump replacement and bilge pump rewire, ground bus replacement, two new deck hatches for access, transom and deck screw hole repair, trying to keep up with coast guard and ABYC standards, etc...

have all ready made the three or four "final" purchases, (more 5200, more marine silicone, float switch for pump, more hose clamps, 4000uv, etc).

I cant really afford Bondo glass, or interlux, or more sandpaper, or primer.

If i can find a good temporary solution for the epoxy UV protection, i need to take it. I can finish it the right way in the fall.

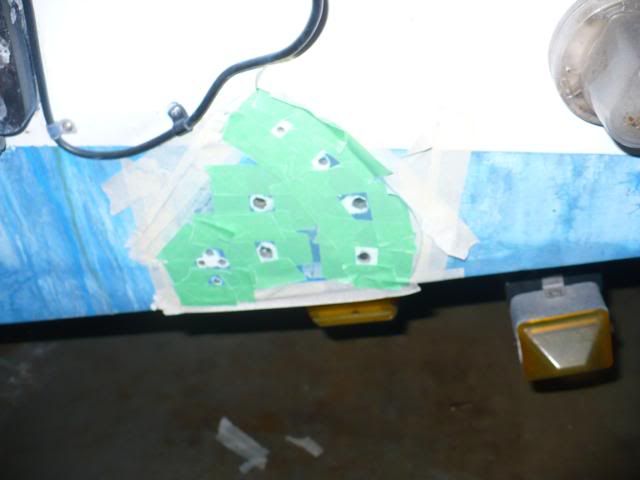

For reference, I am talking about 10-15 dime sized epoxy filled holes on the transom and four 1/4 inch epoxy filled holes on the deck.

Last thing i want to do is half-assed, but when the moneys gone, its gone. Can I cover each spot with a uv resistent silicone, or 3m 4000UV, or is there something i can get at the hardware store that will do the trick.

Sorry for the depressing tone of the post. I am very pleased with the progress and look forward to getting more pics up. I just need to solve this problem and hope the rest of the install goes smooth.

Here's what I am looking forward to (minus the goofy hat and coat)