Hi All- so I picked up an '01 205 Osprey and there is a ~5foot section on the aft starboard side where the hull is separated from the rub rail/ deck cap. If I apply light pressure to the hull around the 'aquasport' lettering, a gap of about 0.5-0.75" opens up and I can see daylight if I look through the gunwhale rod holder holes on the inside. First question is how are the upper and lower molds originally connected? Are they sealed + screwed/riveted (I think so?) or is it glassed after assembly? Second question, has anyone had an issue like this and how did you correct it?

I am thinking that I will

1) Remove the rub rail for that section

2) Fill existing screw holes on the hull side of the seam with something like 5200 since I am guessing the screws pulled through the fiberglass there

3) Use thickened epoxy (six10?) in the seam between the hull and the deck

4) Re-Screw or rivet the seam

5) Caulk the seam??

6) Re-install rub rail

Am I way of base? Will this be ok structurally? Should I use something besides 5200 or six10? Are screws or rivets better to use? They will all be blind rivets- is there a trick to getting them to hold better/ not pull through again?

This is the section of the boat where it is separated:

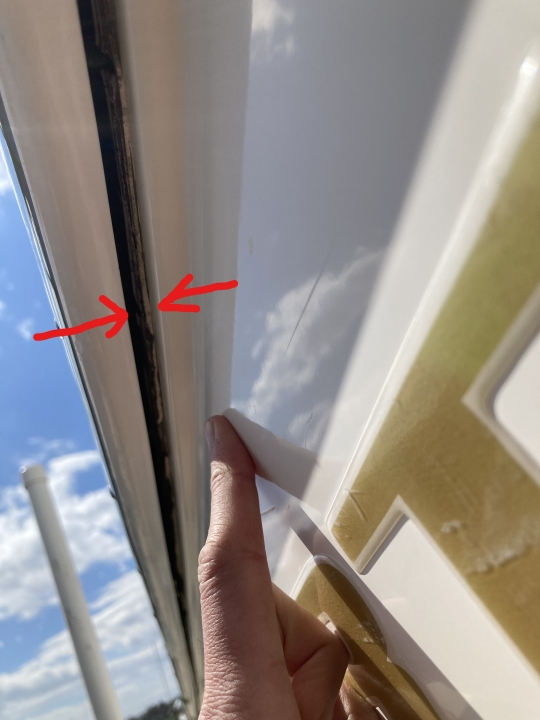

This is what the gap looks like when I apply light pressure. Its about 3/4" with a couple pounds of pressure

Thanks in advance

-CD