11

246/250 CCP Rebuilds / Re: Project - Aquasport 246CCP, 1979, Captain Koz II

« Last post by kaptainkoz on June 30, 2025, 01:26:37 PM »If at first you don’t succeed ….

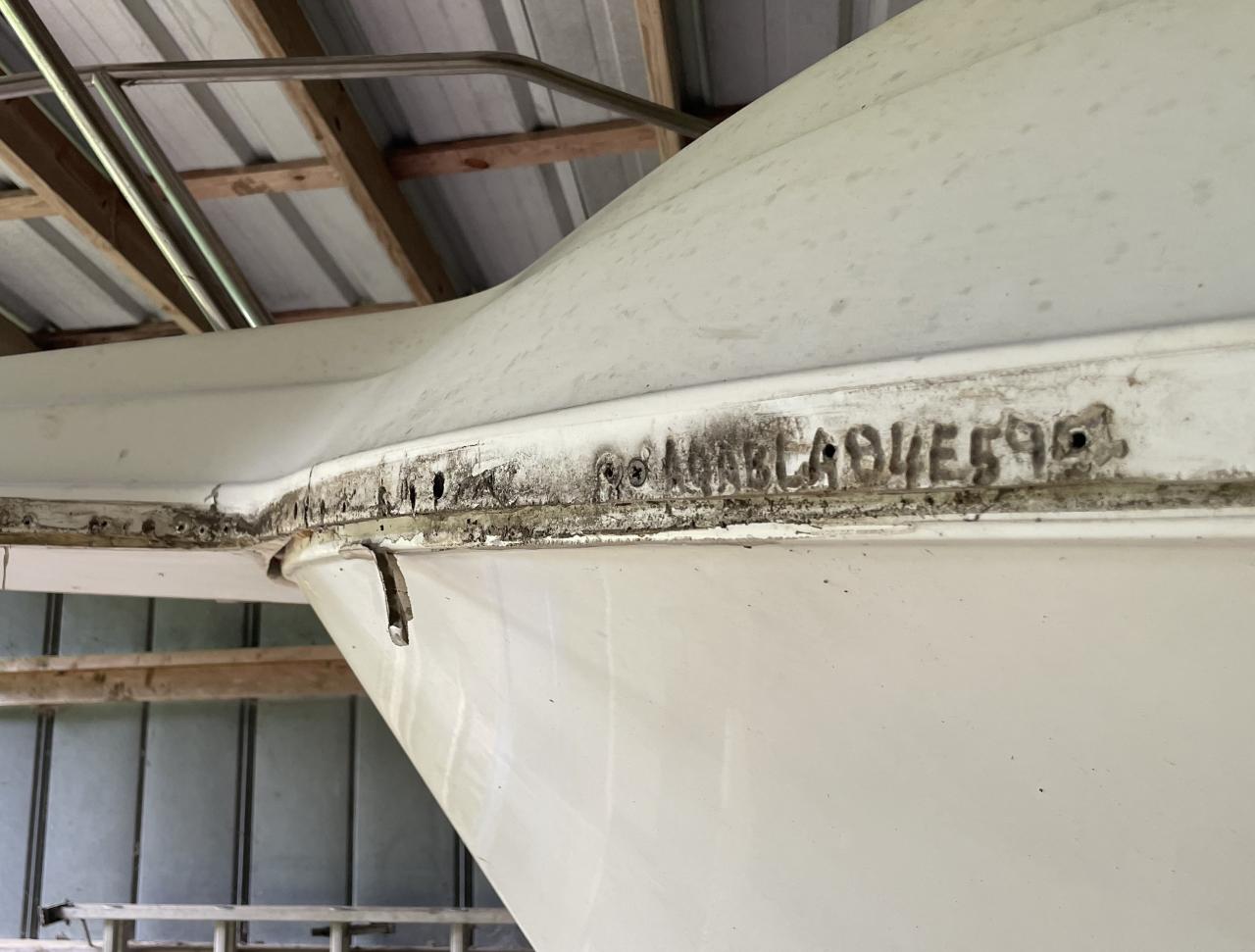

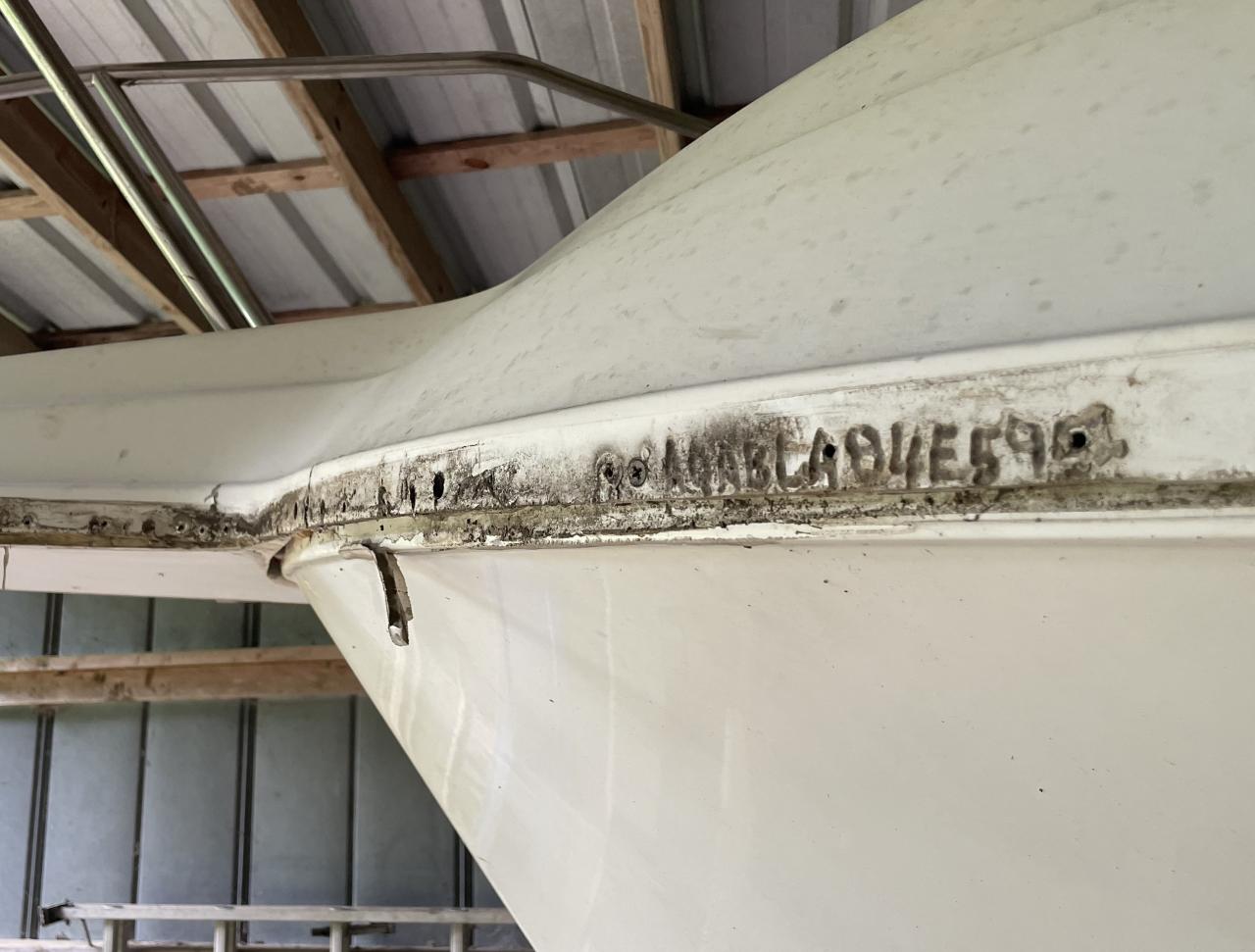

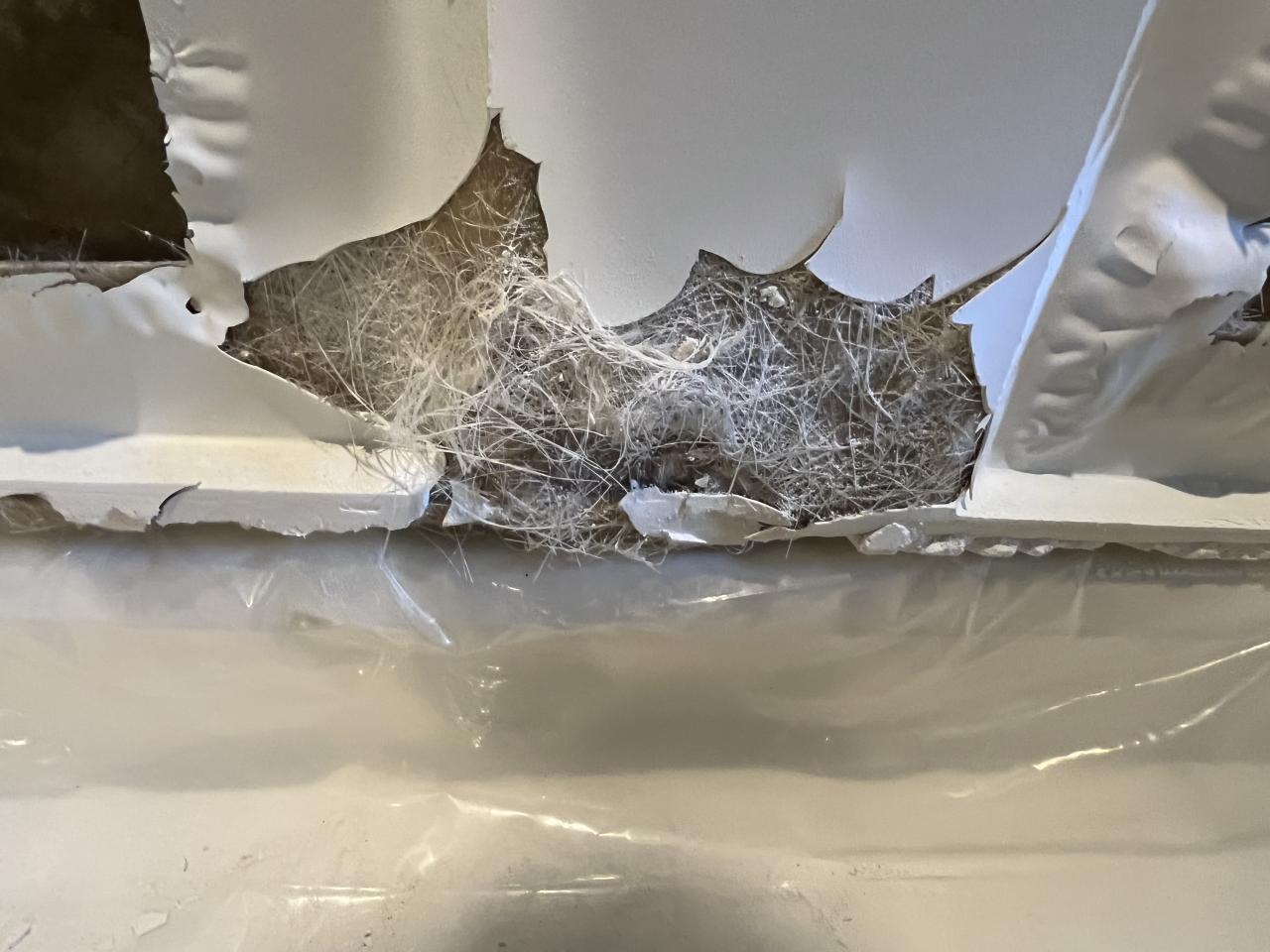

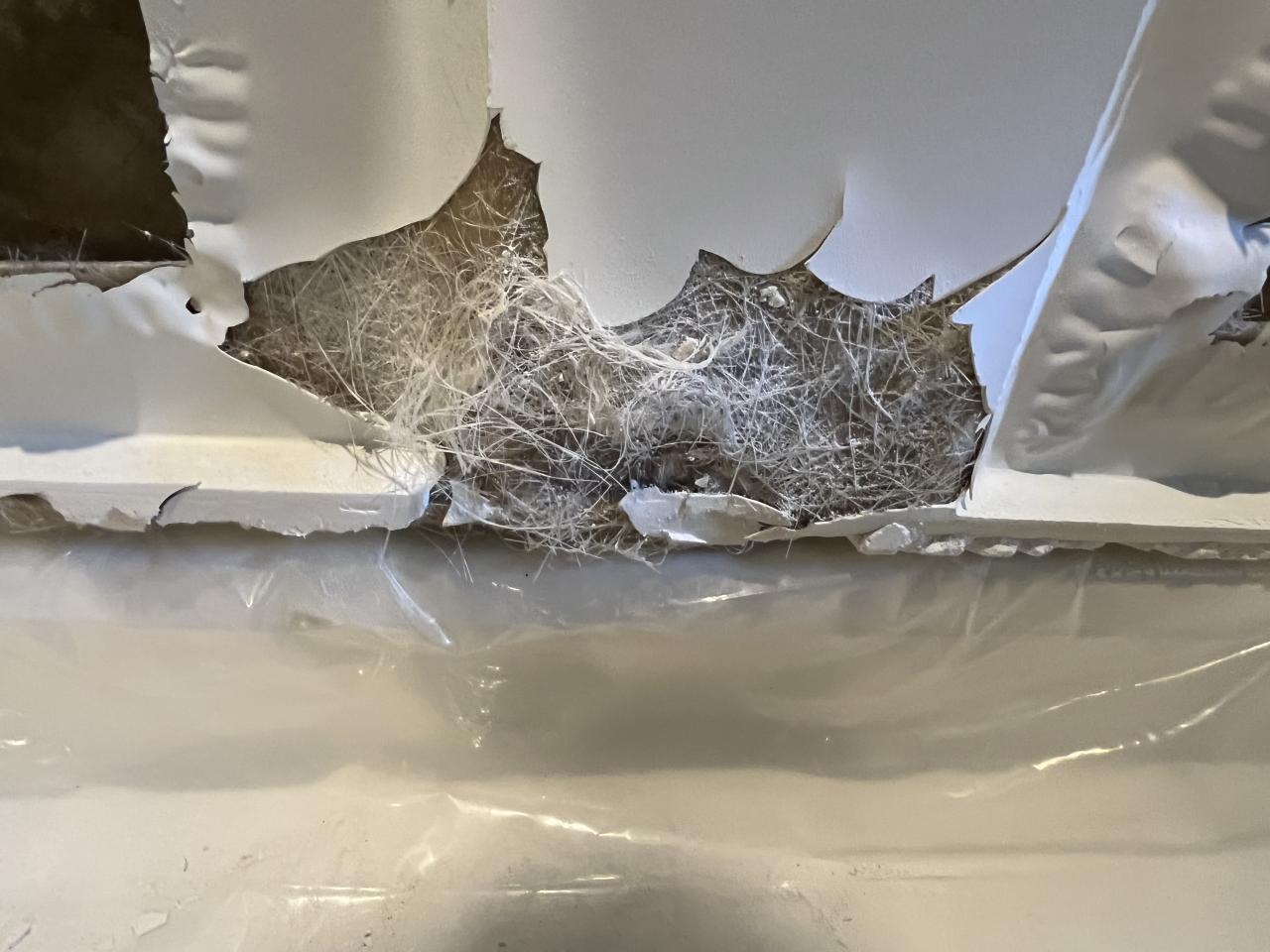

Well damn. It’s a disaster. I am not sure what happened. I want to surmise that the first layer veil-thin 1.5 CSM never full cured? The CSM in the photos is still partially wet and sticky. There are hollows behind some of the gel as if I missed a whole section which is impossible as I fillet every corner with peanut butter and lay 1.5 CSM over it. I have a few small sections that are soft even through all 3 layers of 1708 as if none of them in a 3” section cured. Did the dura tec have an affect? But then again I have one small section of 3 layer 1708 that is soft. It would look like I didn’t add enough MEKP but it is very inconsistent and seems to be in some of the corners. Yes I stir aggressively with a large piece of wood when I add mekp. Not my first mold either. I have never seen this before. Was it the high humidity? Not enough cure between layers? I shake the resin bucket every time to make sure nothing is settled. Most of it cured perfectly but a few spots didn’t. I don’t understand what happened. Does anyone have an idea of what went wrong?

However, on the bright side… that “1 inch” that I referred to in prior posts is definitely bothering me and will be 2 inches in the next try. Yes, I’m going to start from scratch and build another mold. I have to. I love how the piece came out and with a few adjustments it will be perfect enough for me. Really bummed to have to do this all over again but kind of grateful for the opportunity to improve on the design. As large as it is I think it only weighs 30-40 lbs so it is not a significant weight addition when you tally all that was removed from original. It looks a lot heavier than it is and it is definitely stout enough as built. It’s going to be really good.

There is NO WAY I missed a half inch behind this gel coat.

On the flip side…. Damn that is going to look good!!!!!

Here is how the “fangs” were going to drain water from the gutter

This is where the 2 inches will come in place… 1 inch on each side of the opening instead of the opening ending right on the curves. The lid to the opening will be covered in teak but I want the teak to sit neatly on the gel coat flat and not on the curve.

So today I lick my wounds and am doing a massive clean up and reset in the garage. I have made some mess and have to get everything back in order. I am brining both tables down for a few days as I have some automotive repairs to do then I will regroup and get building. I have to go get more whiteboard as well. Please let me know if it’s obvious to someone what went wrong.

Well damn. It’s a disaster. I am not sure what happened. I want to surmise that the first layer veil-thin 1.5 CSM never full cured? The CSM in the photos is still partially wet and sticky. There are hollows behind some of the gel as if I missed a whole section which is impossible as I fillet every corner with peanut butter and lay 1.5 CSM over it. I have a few small sections that are soft even through all 3 layers of 1708 as if none of them in a 3” section cured. Did the dura tec have an affect? But then again I have one small section of 3 layer 1708 that is soft. It would look like I didn’t add enough MEKP but it is very inconsistent and seems to be in some of the corners. Yes I stir aggressively with a large piece of wood when I add mekp. Not my first mold either. I have never seen this before. Was it the high humidity? Not enough cure between layers? I shake the resin bucket every time to make sure nothing is settled. Most of it cured perfectly but a few spots didn’t. I don’t understand what happened. Does anyone have an idea of what went wrong?

However, on the bright side… that “1 inch” that I referred to in prior posts is definitely bothering me and will be 2 inches in the next try. Yes, I’m going to start from scratch and build another mold. I have to. I love how the piece came out and with a few adjustments it will be perfect enough for me. Really bummed to have to do this all over again but kind of grateful for the opportunity to improve on the design. As large as it is I think it only weighs 30-40 lbs so it is not a significant weight addition when you tally all that was removed from original. It looks a lot heavier than it is and it is definitely stout enough as built. It’s going to be really good.

There is NO WAY I missed a half inch behind this gel coat.

On the flip side…. Damn that is going to look good!!!!!

Here is how the “fangs” were going to drain water from the gutter

This is where the 2 inches will come in place… 1 inch on each side of the opening instead of the opening ending right on the curves. The lid to the opening will be covered in teak but I want the teak to sit neatly on the gel coat flat and not on the curve.

So today I lick my wounds and am doing a massive clean up and reset in the garage. I have made some mess and have to get everything back in order. I am brining both tables down for a few days as I have some automotive repairs to do then I will regroup and get building. I have to go get more whiteboard as well. Please let me know if it’s obvious to someone what went wrong.

Recent Posts

Recent Posts